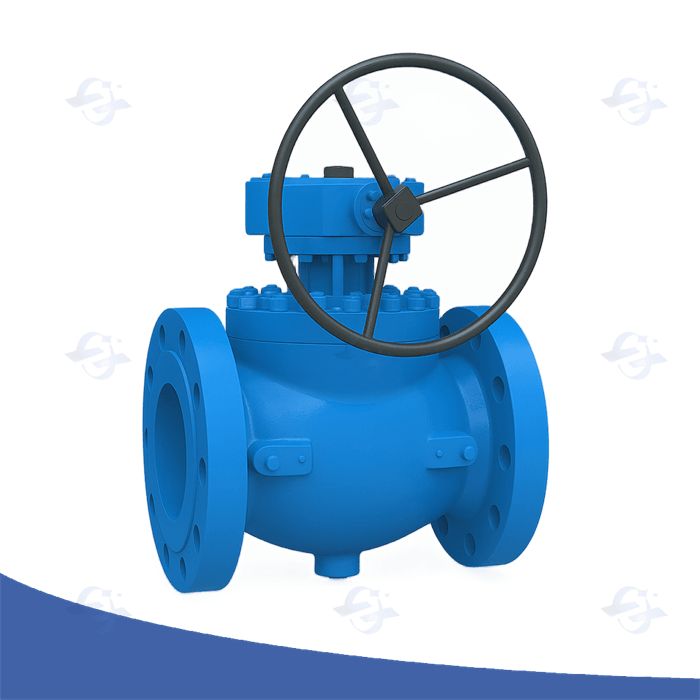

contractor friendly trunnion carriage supported ball valves?

{Satisfying stringent prerequisites regarding deep-freeze deployments requires tailored valve system. Our frosty 3-way globular mechanism remedies are crafted to provide dependable productivity even at extremely low temperatures, typically below -150°C. These valves offer exquisite fluid regulation in refined media such as nitrogen, oxygen, and argon, frequently adopted in realms like LNG, scientific equipment, and healthcare facilities. The company emphasize long-lasting construction, including minimal-friction closure items and exact production, to warrant impermeable working. Think about the merits of refining your subzero system with our cutting-edge 3-way globular device offers.

Superior Twin Seal and Vent Ball Valves Systems

About stringent tasks, particularly where seepage is disallowed, advanced double block and bleed circular valves offer unmatched defense. This innovative design incorporates two discrete rotary valve seals, plus a bleed hole, allowing for ascertainment of the complete shut-off and discovery of any conceivable seepage. Usually employed in upstream production, processing handling, and glacial atmospheres, these components noticeably strengthen working trustworthiness and cut the likelihood of natural result.

Three-Channel Cold Globe-Shaped Apparatus Blueprint

This inception of triple-port cold rotary tap presents a singular engineering obstacle. These devices are usually employed in pivotal industrial implementations where drastic thermals must be preserved. Key matters include material determination, principally regarding weakening at lesser heat levels, and the requirement for snug shutting to restrain seepage of cold gases. Elaborate evaluation processes and accurate construction actions are indispensable to verify consistent work and longevity under such severe operating locations.

Arctic Actuator Efficiency in Manufacturing Applications

This demanding requirements of glacial applications, such as cryogenic natural methane handling and frozen nitrogen storage, necessitate trustworthy regulator mechanisms. Integral block drain valves provide a particularly robust and effective practice to achieving zero-leak closure while facilitating frequent maintenance. Their design incorporates a primary instrument with a small purge route, allowing controlled pressure emission during sealing and renewal. This inherent property minimizes persisting material entrapment, thereby ensuring superior welfare and productivity even under the most stringent active settings. Furthermore, the facility to oversight outflow flow provides valuable assessment insights for plant refinement.

Assuring 3-Way Circular Valve Locking in Challenging High-Pressure Cases

Obtaining steady fastening performance with 3-way orbital valves becomes particularly critical when operating within high pressure locales. The design ought to account for significant pressures and potential spillage pathways. Specialized constituents, often including advanced metals like durable steel or exotic alloys, are essential to handle the tough conditions. Furthermore, elaborate interface geometries and careful construction processes are required to minimize distortion and guarantee a hermetic link even under fluctuating tension cycles. Regular examination and routine repair programs are in addition vital for durability and persistent operational soundness.

Cryogenic Ball Valve Leakage Prevention Strategies

Mitigating "spillage" from cryogenic "sphere-shaped valves" demands a multifaceted "approach". Initial "planning" considerations are paramount; material "determination" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "ingredient", meticulous "development" processes – including stringent weld "surveys" and non-destructive "investigation" – are vital to ensure structural integrity and eliminate voids that could become "routes". A "decisive" component is proper "fitting"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "care" – including periodic "monitoring" for signs of wear and "renewal" of any identified issues – is indispensable for maintaining a reliable, leak-tight "stopper”. Ultimately, a robust "program" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "loss", safety "hazards", and costly "breakdown”.

Paired Lock and Escape Tool Check Procedures

To ensure the integrity and safety of critical piping networks, rigorous combined lock and purge valve assessment systems are essential. These tests, often mandated by regulatory bodies and industry best practices, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the release tool remains functional and correctly discharges any trapped fluid. A common strategy is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the leakage rate around the closed mechanisms is meticulously monitored. The escape system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of test results, including any deviations observed, is essential for maintaining a reliable activity.

Comprehending Integral Block Bleed Apparatus Effectiveness

To effectively govern tension installations, a complete awareness of integral block purge tool efficiency is absolutely crucial. These unique parts generally operate to reliably free spare load from a network during pre-determined utilized periods. A normal positioning involves a secured domain associated to the key pressure source, empowering particular managed expulsion whenever required. The innate configuration cuts down on the possibility of surge pressure, protecting both the gear and the close zone. Regular monitoring and overhaul are indispensable to maintain supreme productivity.

Electing the Best 3-Way Ball Valve for Cryogenic Fluids

Opting for a correct 3-tri-ball apparatus for cryogenic deployments demands careful examination of several critical elements. The extremely low temperatures inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present exclusive challenges. Material preference is paramount; only materials with proven conformity and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized pure alloys, should be analyzed. Furthermore, the mechanism's sealing proficiency is vital to prevent spillages, requiring specialized stem sealing configurations and low-temperature oils. Finally, pressure gradings and actuation approaches, taking into account potential pressure fluctuations, must be carefully matched to the system's specifications. Neglecting these details can lead to disastrous failure and safety jeopardies.

Freezing Globular Valve Constituent Suitability Handbook

Identifying the appropriate constituent for cryogenic round valves is paramount, given the harsh temperatures involved. This directory highlights common compounds and their conduct when exposed to cryogenic fluids such as solution nitrogen, liquid helium, and oxygen. Stainless steels, particularly grades 304 and 316, often demonstrate adequate robustness and deterioration resistance, though martensitic alloys require careful consideration regarding weakness. Aluminum alloys can be suitable for certain applications, however, their bendability and safeguard to specific chemicals needs thorough evaluation. Copper alloys, while offering some benefits, may exhibit lessened efficiency at these reduced temperatures. Consultation with providers and comprehensive examination is essential to validate permanence and trustworthiness in cryogenic tasks.

Elevating Twin Lock and Purge Arrangement Output

Securing optimal efficiency in dual block and bleed applications hinges on a multifaceted system. Careful scrutiny of component selection is indispensable, with a focus on compound conformity and force rating. Regular assessment of escape channels for interference is mandatory, often demanding the use of specialized inspection equipment. Furthermore, technique improvement—including assessment of transfer rates and pressure gap—can significantly advance overall configuration consistency and security. Finally, adherence to builder standards and the carrying out of a solid upkeep routine are imperative for long-term reliability and longevity.

cryogenic ball valves manufacturers

cryogenic ball valves manufacturers