market leading asset protecting pigging solutions for pipeline care?

Inside the scope of industrial workflows, protecting the unity and capability of passages is critical. Concentration of dirt within lines can dramatically retard stream velocity, undermine commodity level, and augments maintenance outlays. To handle these difficulties, duct washing approaches have appeared as particularly powerful answers for effective channel cleaning. A apparatus, commonly a tubular implement, is transported through the line, successfully scrubbing impurities and maintaining top functionality

Pigging systems frameworks grant several advantages. They are modifiable, suitable for cleaning channels of assorted diameters and ingredients. Furthermore, they are effective, completing the work in a notably swift stretch. By lessening downtime and improving pipeline functionality, pipeline cleaning systems contribute to fiscal gains and elevated operational performance

Purity Focused Line Methods:

Preserving pipeline pristineness is indispensable for guaranteeing offer assurance and quality of carried materials. Sanitary pigging systems supply a dependable way to realize this end. Pigs, tailored gadgets, are introduced into pipelines to decontaminate by getting rid of residues and filth

- Myriad types of sanitary pigs are offered, each crafted for dedicated cleaning activities.

- These pigs are constructed from components that fulfill stringent hygienic standards.

- Consistent sanitary pigging exercises assist reducing product meaning loss, extend pipeline service life, and improve holistic performance.

Sophisticated Pigging Technologies for Top Operation

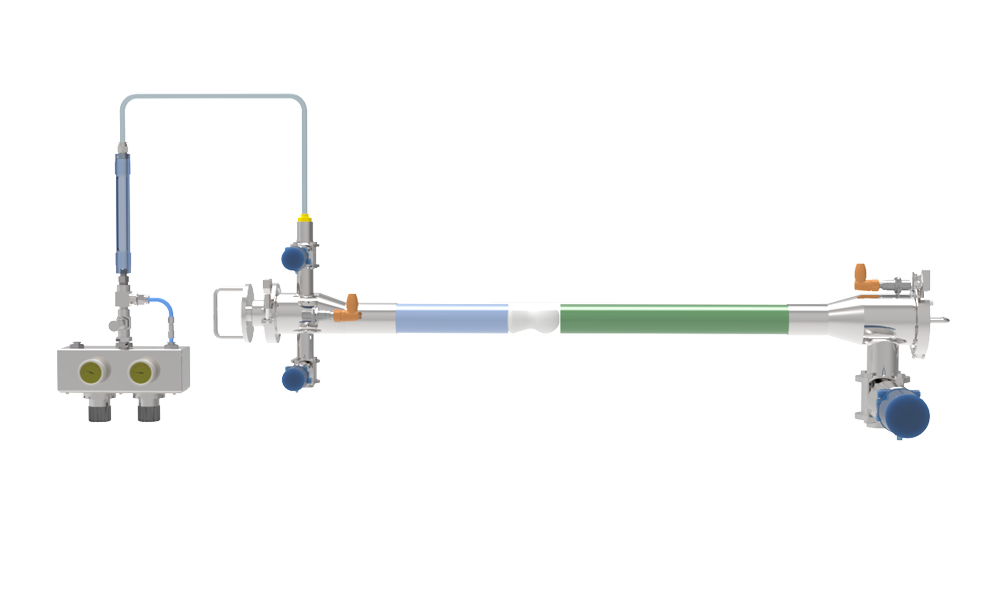

pigging productsIn the sector of line repair, leading pigging methods have grown into a primary technology for guaranteeing superior effectiveness and shielding. These frontline systems utilize inventive layouts and performances to adeptly sanitize, analyze, and maintain pipelines from damage. From automated pigs provided with concurrent checking attributes to focused pigging tools intended for intricate tasks, evolution in this discipline is incessantly extending scope. By exploiting these enhancements, executives can materially advance pipeline firmness, curtail downtime, and augment operational capability.

Broad Pigging Setup Engineering and Fitting

Such wide-ranging pigging system entails a essential approach for pipeline upkeep. This routine embraces the fitting of designed instruments called pigs, which move through pipelines to sterilize, evaluate, and secure their stability. The layout prioritizes variables such as channel size, material, pig form, and operational specs. A intelligently crafted system ensures productive pigging activities while cutting down downtime and potential failures. Installation steps push for careful management, skilled specialists, and strict adherence to safety guidelines to enable a stable and effective effectiveness

Professional Pigging Tools for Multifaceted Employments

Industrial pigging instruments are essential instruments incorporated across a extensive series of industries. These products facilitate sound and efficient disinfecting, review, and conservation of lines and other hollow edifices. Pigging entails installing custom apparatuses known as pigs through pipes to perform a variety of operations. Regular types of industrial pigging devices contain cleaning pigs, inspection pigs, and carrier pigs. Cleaning pigs are fabricated to extract debris, build-up, and residues from pipelines. Inspection pigs are installed with sensors that accumulate information about the condition of pipe coatings. Transport pigs are utilized to convey contents through pipelines. The use of industrial pigging products offers numerous virtues, such as diminished downtime, strengthened pipeline robustness, and increased operational output. These instruments are frequently employed in realms such as oil and gas, water treatment, chemical production, and food manufacturing.Full Examination of Pipeline Pigging

Pipeline pigging is an essential technique used within the oil and gas domain to audit pipelines. This necessary process comprises installing custom units, designated as pigs, into the passage. Pigs are constructed to pass through the coverage of the pipeline, conducting various roles.

Several classes of pigs are at one's fingertips, each built for a distinct purpose. Common employments of pipeline pigging entail testing for defects, flushing, and applying coatings.

- Advantages of Pipeline Pigging

- Influences on Operational Efficiency

- Classes of Pipeline Pigs

Dependable Sanitation by means of Pigging Methods

Pigging arrangements contribute a sound answer for promoting sanitation inside passages. These systems employ custom-made devices that travel through the pipe infrastructure, effectively removing deposits. The method is especially beneficial for industries that demand rigorous hygiene measures. Pigging approaches supply a cost-saving and fast approach for washing tubes, mitigating the possibility of cross-contamination.

Choosing Pigging Equipment for Exclusive Prerequisites

Pigging machinery acts a key role in successful pipeline functioning. When appointing pigging machinery, it is indispensable to consider the unique requirements of your assignment. This embraces reviewing elements such as pipeline diameter, flow flux, product class, and repair requirements.

Countless pigging models are available, each developed for distinct missions. As an example, some pigs are meant for assessment, while others are deployed for eradicating debris or distributing product quantities.

Additionally, pigging gear elements should be agreeable with the conveyed material.

It is typically advisable to seek advice from a authority in pigging solutions to secure that you elect the most appropriate hardware for your particular demands.

Conduit Maintenance Methods - A Practical Approach

Flow line pigging present a comprehensive selection of assets for fields focused on pipes. By skillfully purging and assessing pipe interiors, pigging systems raise operational capability and decrease maintenance outgoings.

A principal virtue of pigging systems is their ability to eradicate build-up such as mineral deposits, debris, and oxidation products. This consistent hygiene ensures unobstructed pipeline passage and reduces costly downtime.

Furthermore, pigging systems can be implemented to examine the condition of pipelines, finding foreseeable problems before they worsen into substantial issues. This preventative tactic enables to extend the lifespan of pipelines and minimize overall maintenance budgets.

Preserving Hygiene in Pigging Workflows

Swine breeding setups essentially emphasize appropriate hygiene practices to reduce the circulation of virus. Enforcing rigorous hygiene routines promotes a wholesome milieu for pigs, whereby produces advanced health outcomes and production.

Detailed cleaning and disinfection of premises is critical to reduce the level of harmful germs. Efficient feces management besides holds a vital part in supporting hygiene.

What's more, {workers